| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : joonpang

Model Number : E-141

Place of Origin : china

Certification : OEM

MOQ : 10000pcs

Price : NA

Packaging Details : carton

Delivery Time : 15days

Payment Terms : T/T

Runner System : Hot/Cold

Mold Base : LKM, DME, HASCO, Etc.

Size : Customized

Surface Finish : Polished

Color : Customized

Mold Life : 500,000 Shots

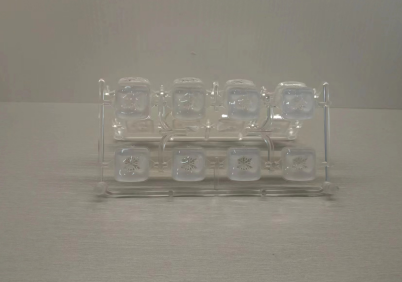

Usage : Mold For Producing Plastic Housing For E-cigarettes

Application : E-Cigarette

Polished Plastic E Cigarette Accessories for Enhanced Vaping Experience

Creating an injection mold for e-cigarette plastic housings requires meticulous planning, precise design, and strict adherence to industry standards. This process involves a lot of steps where even the slightest error can result in defects and improper fitting of e-cigarette plastic housings. To ensure optimal results, it is recommended to partner with mold designers and manufacturers who have years of experience in the industry.

Collaboration with professionals in this field can streamline the mold-making process, from designing the mold to testing and quality checks before moving to mass production. By having an experienced partner, you will be able to anticipate potential problems and address them before they arise, avoiding costly mistakes that often delay production or require significant rework.

By adhering to industry standards, your injection molding process will be faster, cheaper, and yield higher-quality results. These standards are designed to ensure that injection molds are effective, efficient, and compatible with most conventional molding equipment. Sticking to industry standards also guarantees that your e-cigarette plastic housings will meet the required regulatory requirements, affirming their safety for use.

Below are some commonly manufactured parts made through injection molding:

The industry is moving towards sustainability, with a growing trend of using biodegradable or recyclable materials. This not only helps to reduce the environmental impact of production but also improves the brand image and appeals to environmentally conscious consumers.

Another trend is customization. Many manufacturers are now offering customizable options for brands, providing unique and personalized products. This allows brands to stand out from competitors and create a stronger brand identity.

If you have any specific questions or need information on a particular aspect of e-cigarette plastic injection parts, feel free to ask! Our team is always happy to assist you.

Q1. What is the brand name of the E-Cigarette Plastic Housing Mold?

A1. The brand name of the E-Cigarette Plastic Housing Mold is joonpang.

Q2. What is the model number of the E-Cigarette Plastic Housing Mold?

A2. The model number of the E-Cigarette Plastic Housing Mold is E-138.

Q3. Where is the E-Cigarette Plastic Housing Mold made?

A3. The E-Cigarette Plastic Housing Mold is made in China.

Q4. What is the certification of the E-Cigarette Plastic Housing Mold?

A4. The E-Cigarette Plastic Housing Mold is certified as OEM.

Q5. What is the minimum order quantity for the E-Cigarette Plastic Housing Mold?

A5. The minimum order quantity for the E-Cigarette Plastic Housing Mold is 10000pcs.

Q6. What is the packaging detail for the E-Cigarette Plastic Housing Mold?

A6. The packaging detail for the E-Cigarette Plastic Housing Mold is carton.

Q7. How long does it take to deliver the E-Cigarette Plastic Housing Mold?

A7. It usually takes 15 days to deliver the E-Cigarette Plastic Housing Mold.

Q8. What are the payment terms for the E-Cigarette Plastic Housing Mold?

A8. The payment terms for the E-Cigarette Plastic Housing Mold are T/T.

|

|

Plastic Electronic Cigarette Small Components Injection Molding Polished Surface Images |