| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

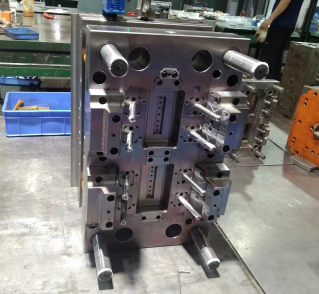

Brand Name : joonpang

Model Number : B-3

Place of Origin : china

Certification : OEM

MOQ : 1SET

Price : NA

Packaging Details : carton

Delivery Time : 30days

Payment Terms : T/T

Mold Base Standard : HASCO, DME, LKM, Etc.

Mold Base Features : High Precision, Durable, Easy To Use

Mold Base Size : According To Customer's Requirements

Ejector System : Ejector Pins

Mold Base Life : 500,000-1,000,000 Shots

Mold Base Warranty : 1 Year

Mold Base Application : Plastic Injection Molding

Runner System : Hot Or Cold

Components

A mold typically consists of several components that work together to create a finished part. These components include:

Mold bases are typically constructed from steel or aluminum, with the material selection being guided by considerations like the desired production volume and compatibility with other materials. The type of metal used can have important implications for factors like the overall durability and longevity of the mold, making it an important decision for those involved in the manufacturing process.

When designing molds, there are several important factors that must be taken into account. One of the most pressing considerations is durability, as molds must be able to withstand repeated cycles of high pressure and temperature without warping or breaking down.

Another key consideration is precision. The dimensions of a mold must be incredibly accurate to ensure that the final part meets the desired specifications and fits together with other elements as intended. This often requires the use of complex computer modeling and precise manufacturing techniques.

Finally, ease of maintenance is another important design consideration. Molds must be designed in a way that allows for quick and easy access for maintenance and repairs when needed. This can help to minimize downtime and keep production moving smoothly.

Applications:

The utilization of plastic parts has become vital in numerous enterprises such as automotive, consumer goods, and electronics. These plastic parts are widely utilized in the following areas:

The versatility of plastic makes it a popular choice in these industries. The ability to use different types of plastic materials enables the creation of various shapes, sizes, and styles of plastic parts for use in products and applications.

FAQs for joonpang Plastic Injection Mold Base (Model Number: B-1)

Q: What is the place of origin of the joonpang Plastic Injection Mold Base?

A: The joonpang Plastic Injection Mold Base is made in China.

Q: What is the certification of the joonpang Plastic Injection Mold Base?

A: The joonpang Plastic Injection Mold Base is OEM certified.

Q: What is the minimum order quantity for the joonpang Plastic Injection Mold Base?

A: The minimum order quantity for the joonpang Plastic Injection Mold Base is 1 set.

Q: What are the packaging details for the joonpang Plastic Injection Mold Base?

A: The joonpang Plastic Injection Mold Base is packaged in cartons.

Q: What are the payment terms for the joonpang Plastic Injection Mold Base?

A: The payment terms for the joonpang Plastic Injection Mold Base are T/T.

|

|

Steel Plastic Injection Mold Base Standard Or Customized Ejector System Ejector Pins Images |